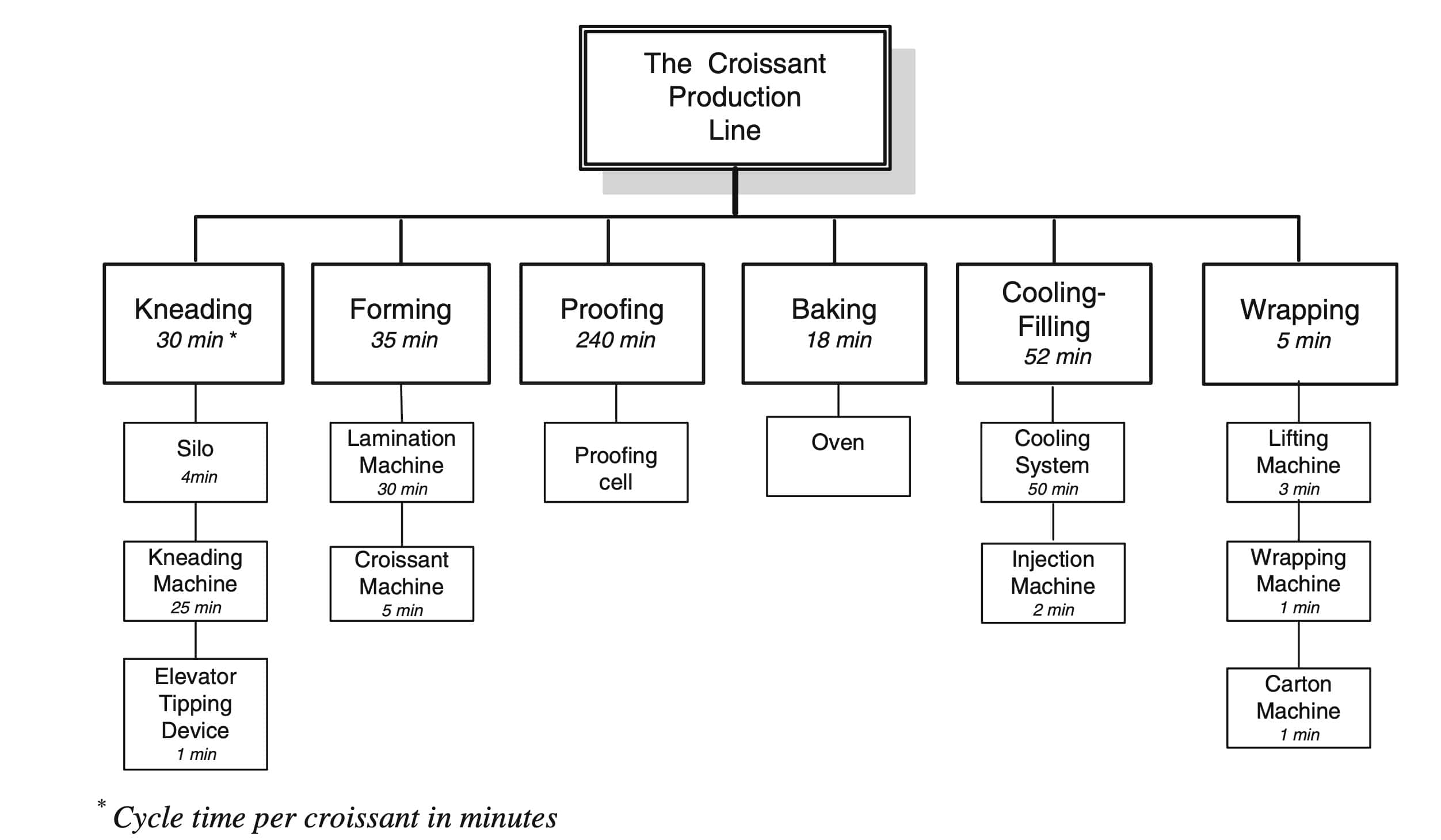

Croissant Production System

Typically, the croissant line consists of six independent workstations in series integrated into one system with a common transfer mechanism and control system. Each workstation consists of one-three machines connected in series. The movement of material between stations is performed automatically with mechanical means. There are six distinct stages in croissant production: kneading, forming, proofing, baking, cooling- filling and wrapping. The process flow of the line is as follows.

In workstation 1 (kneading), flour from silo and water are automatically fed into the removable bowl of the spiral kneading machine. After the dough is kneaded, the bowl is unloaded from the spiral machine and loaded onto the elevator-tipping device that lifts it and tips it to moisten the dough into the dough extruder of the lamination machine in the next workstation.

In workstation 2 (forming), the dough fed into the lamination machine is laminated, folded, reduced in thickness by a multiroler and refolded a few times by a retracting unit to form a multi-layered sheet. The multi- layered dough is fed into the croissant-making machine, which cuts it into pieces of triangular shape. Finally, the triangles are rolled up and formed into crescents. At the exit of the croissant-making machine, the croissants are laid onto metal baking pans, and the pans are inserted into carts.

In workstation 3 (proofing), the carts are automatically pushed into the proofing cell, where they remain under strict uniform temperature and humidity conditions for 240 min so that croissants can rise to their final size.

In workstation 4 (baking), the carts are automatically pushed from the proofing cell to the oven. The baking pans are unloaded from the carts and are placed onto a metal conveyor that passes through the oven. The baking pans remain in the oven for 18 min until the croissants are fully baked.

In workstation 5 (cooling-filling), the baking pans with the baked croissant remain on the conveyor and follow a trajectory (cooling system) for 50 min to cool the croissants down and avoid any condensation phenomena (drops) after packaging. The croissants may then be filled with an injecting machine.

In workstation 6 (wrapping), the croissants are automatically lifted from the trays and are flow-packed and sealed with an electronic wrapping machine. The final products are picked up and placed in cartons. The filled cartons are placed on a different conveyor that takes them to a worker who stacks them onto palettes and transfers them to the finished-goods warehouse. The empty baking pans are automatically returned to the croissant-making machine.